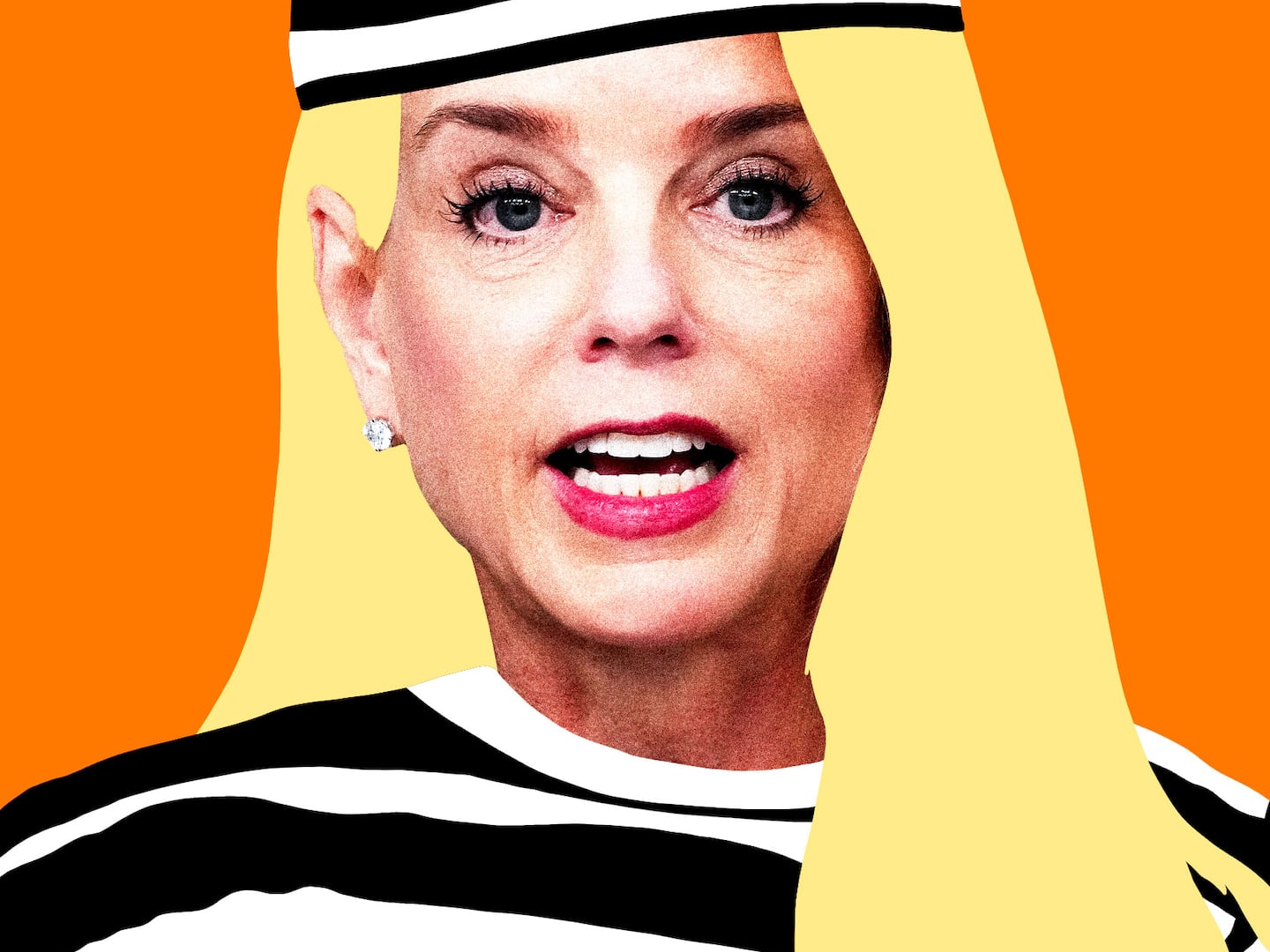

No one expects to find alive the four missing miners in the Montcoal explosion, but rescue workers entered the mine Thursday morning to look for them. Rescue operations had been slowed by the necessary ventilation of noxious gases such as carbon monoxide, which is lethal, and the explosive gases hydrogen and methane, which have been blamed for the blast. Joan Quigley, author of The Day The Earth Caved In: An American Mining Tragedy, talks to mining experts about the factors that still make mine safety an elusive quest. Plus, our gallery of mining disasters and rescues.

Long before iPads and Twitter, coal miners perished underground. In an era of Foursquare and downloadable apps, when a $99 iPhone can pinpoint the closest subway entrance or taxi and double as a GPS, coal miners still die at work, hundreds of feet beneath the surface. The question, of course, is why?

It is too soon to know what happened inside West Virginia’s Upper Big Branch mine, where at least 25 workers died Monday in an underground explosion—the worst American mining accident since 1984. And with state and federal officials focused on rescue and recovery, the explanation will unfold over months and years, as investigators prepare and file their reports. But even in a digital world, the fundamentals of mining safety remain enshrined in nineteenth century treatises, the mine-engineering equivalent of housekeeping, albeit with higher stakes.

Click Below to View Our Gallery of Mining Disasters and Rescues

“This ain’t rocket science,” said J. Davitt McAteer, a vice president at Wheeling Jesuit University and a former federal mining official in the Clinton administration. “You can do this if you put your mind to it.”

• More Photos and Video of the Mining TragedyBy several criteria, the industry has burnished its safety record, even as production has surged. Coal-mining fatalities peaked in 1907, when 3,242 workers died, and have dwindled since, with a record low of 18 deaths in 2009, according to the U.S. Mine Safety and Health Administration. MSHA has also stepped up enforcement. In 2009, the agency issued 102,660 citations and orders against coal operators, almost a two-fold increase from 2003, and assessed more than $103 million in fines, almost a ten-fold increase in the same period, according to data on its web site.

In a statement on its web site, Massey Energy Company, which owns Upper Big Branch, hailed 2009 as the sixth consecutive year, and the 17th year out of 20, when its safety performance was stronger than the industry average.

Still, experts concede 21st century mine safety remains an elusive quest, tethered to discipline and vigilance.

“The simplest answer is that in the world of mining—as opposed to the world of computers—chaos has not been taken out of the equation,” said McAteer. “Mining is a dynamic process.”

And when, as in mining, the workplace physically moves every 24 hours, the potential perils abound. Imagine someone rearranging the keys on your computer keyboard every day, said McAteer. That’s what it’s like to toil in a mine: Each shift heralds a new set of conditions to monitor and master, from the mine roof overhead, with its inherent risk of collapse, to potentially flammable mining byproducts, such as coal dust and gases.

Given the day-to-day challenges, mine-safety experts have long perpetuated a prevention-based culture. Like hospital administrators, they focus on minimizing injuries and accidents at all levels, from shift workers and supervisors to mine owners and regulatory authorities. Indeed, MSHA’s comprehensive enforcement scheme—a digital download zaps 20 MB of space on a hard drive—serves as both a template for best practices and a reminder of the industry’s past.

“All those regs have been written in blood because people died and were injured,” said Robert L. Ferriter, senior safety and health specialist at the Colorado School of Mines. “If [operators] comply with the regs and don’t take short cuts, they’ll have a safe operation.”

Still, pockets of resistance remain.

“It’s a constant battle for everyone involved to take care of this,” said Jerry Stewart, the mine safety manager for Ohio’s Department of Natural Resources. “We keep being reminded that we have to work every day to reduce these hazards.”

Even a cursory glance at MSHA records suggests Upper Big Branch, operated by Performance Coal Company, was no stranger to regulatory scrutiny. In the first three months of 2010, the mine amassed 10 citations related to its ventilation plan; federal inspectors logged the most recent infraction on March 30, a week before the explosion. In 2009, the facility notched more than 500 citations—more than twice the 2008 total—and regulators proposed $897,000 in penalties. Meanwhile, between 2008 and 2009, annual man-hours at the site spiked from 395,000 to 482,000—a 22 percent increase, while output more than tripled, soaring from 364,000 tons to 1.2 million tons.

“It’s a terrible trend,” said Ferriter.

In the mining industry, the tradeoff between productivity and safety can have potentially tragic ramifications. “It’s just a failure of will,” said McAteer. “It’s not a failure of knowledge.”

Joan Quigley is the author of The Day The Earth Caved In: An American Mining Tragedy.