Much of the discussion around the fate of General Motors has centered around its supposedly bloated cost structure. GM has a lot of problems, but cost is a relatively minor one, especially now. If GM's bankruptcy plan is accepted, it will cut its debt burden from $172 billion to $17 billion, freeing up a lot of cash that used to go to debt service.

GM's key problem is not costs—it’s price. Specifically, its cars sell for $2,000-$3,000 less than comparably equipped Japanese cars, and people still don’t want to buy them (GM has been losing market share at the rate of one percentage point per year for decades). Labor costs and most other intangibles that affect profitability are dwarfed by this lost amount of revenue.

GM’s cars sell for $2,000-$3,000 less than comparably equipped Japanese cars, and people still don’t want to buy them.

So how does GM boost the price of its cars? The company thinks that perception is part of the issue. They’re right—they are making better cars now—but larger leaps need to be made, and those can come from two areas: building capability with suppliers, and flexibility in manufacturing.

On the supplier side, the automakers don't need new capital; they need a new way of working. Car performance depends in large part on quality of the parts and how smoothly they fit. Automakers typically don’t own their suppliers, but have substantial power over them. (Even in their current desperate straits, the Big Three automakers are buying $7 billion in parts per month.)

In the past, they’ve tried to cut costs with suppliers by pitting them against each other. This technique is great for squeezing suppliers' margins—and GM has been really successful with this, to the point that many suppliers are in bankruptcy. But this method doesn't produce good cars—it doesn't even produce cheap cars, since the price per piece of the component is only a small part of the true cost associated with a part. The true cost also includes the cost of installing that part, of reengineering the part to fix production problems as they arise, and of repairing finished cars should the parts fail while still under warranty.

GM can learn a lot from Honda and Toyota in this regard. These automakers don’t use competitive bidding, yet still make very strenuous performance demands on suppliers. Often they start with an incredibly useful technique called “value analysis,” which involves a rigorous joint examination of each step in the design and production process: Is this step necessary? Could it be done more cheaply?

This process both saves money and increases quality in the long run. How can it do this? Here’s one example: Engineers usually go back to previous versions of a part to design the new one. It could be that some process steps are no longer necessary in the new version—a part that used to be visible to the customer is now hidden, so it doesn’t need a polished surface. Without value analysis, the supplier would not know that the step was not necessary, and the customer might not realize that the step was costly.

Another example comes from an area where consumers find U.S. cars particularly irritating: ride quality. Ride quality is a “systemic” feature of the car—it is determined by the way the parts interact with each other. For example, automakers are now introducing electric steering, replacing hydraulics. The new design is smaller overall, but now features a control module that is very sensitive to heat. Since the product is new, it’s not known exactly how sensitive. Can it be 50 millimeters away from the exhaust, or does it have to be 55 millimeters? Will the changed design cause parts to bump up against each other, causing unpleasant noise or vibration when the car is driven on a rough road? Collaboration with suppliers generates the knowledge needed to solve these problems quickly, saving money and headaches in the long run.

Flexibility in manufacturing is equally important. Until recently, GM was able to make only one car platform per plant, meaning it couldn’t shift production to make more of hot models, and ended up with lots of unpopular cars that it had to get rid of at fire-sale prices. More flexibility requires major capital investments in programmable equipment and sophisticated vehicle carrier systems (U.S. automakers have lagged Japanese firms in these investments for over 20 years)—and much more. Products need to be designed from the beginning to be manufactured on a single flexible assembly line, including such details as having common attachment points from the car’s frame to the carrier that moves it along the line. Finally, in the inflexible factories of the past, there was little incentive for GM to invest in preparing workers to handle a changing product mix. For foreign competitors, flexible technology and a flexible workforce go hand in hand; for GM, not investing in the former meant never seriously pursuing the latter.

The government-appointed directors on the “new GM” board could play a key role in freeing GM from the short-term financial thinking that has imprisoned its leaders for decades. A better suppler system and more flexibility will directly lead to better cars that command higher prices at relatively little marginal cost, once the investments are made. Then the government can sell its stake at a good price, producing a happy ending for taxpayers, workers, and car owners alike.

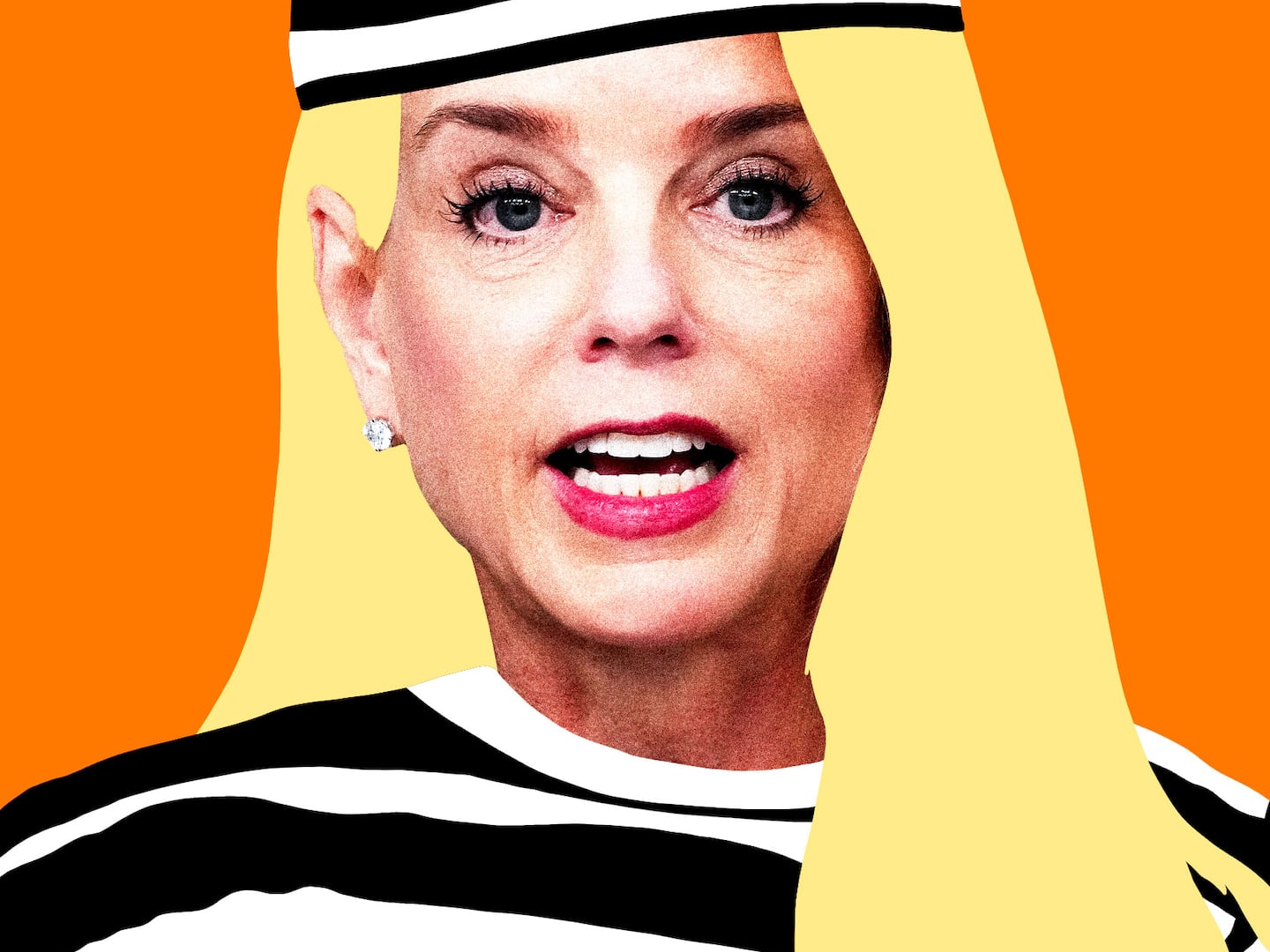

Susan Helper is professor of economics at Case Western Reserve University and a research associate of the International Motor Vehicle Program.

John Paul MacDuffie is associate professor of management at the University of Pennsylvania's Wharton School and co-director of the International Motor Vehicle Program.